Egå Renseanæg (WWTP), the future is here.

I had mentioned in my first blog that the history of wastewater has been rooted in sustainable practises. My exact quote was, “what is more sustainable than taking unusable water and making it usable again.” I may have to modify this statement a bit; there IS something more sustainable… it is not just taking unusable water and making it usable again. It is now possible to take the next step and recover resources from this process. Even though this may sound like some futuristic sci-fi fantasy, it is the reality at the Ega wastewater treatment plant in Denmark.

Egå has recently completed some major improvements to the wastewater treatment process. The implementation of this newer technology focuses on striving for 150% energy efficiency. They are taking a product (wastewater), that many people rarely think about and lets face it usually avoid, and are producing usable necessary products. They are doing all this while providing a required service AND protecting the environment. I am not sure if there are many other companies or services that are able to produce these kind of impressive results but Egå is the future of wastewater. They have inspired people to rethink wastewater and view it as a resource instead of simply a necessary public health requirement and nothing more.

How do they do this you ask? Here are some pictures and diagrams to help better understand what innovative projects are taking place at Egå.

Inlet (#2 on Flow diagram)

Screens (#3)

Scum/Grit Chamber (#5)

After the pretreatment is the Salsnes filter. The Salsnes filters are a new technology that replaces much of the primary treatment. Here is how it works…

Salsnes Filters (#7)

In the same building as the Salsnes filters is the biogas engine and the future location of the Organic Rankine Cycle (ORC) (#23)

Biogas Engine (#22)

Additional to the energy efficient equipment that have been installed at Egå there is also a sidestream anammox process (DEMON) and eventually a mainstream cold anammox process, that will allow the plant to stay within the limits of their permit. The current limits on Total-P is 0.4 mg/L and Total-N is 8 mg/L for Egå.

Top of DEMON Tank (#26)

The following pictures are of the current BioP and nitrification/denitrification (N/DN) tanks

Fermentation Tank (#15)

BioP Tank (#9)

Empty N/DN Tank (#10)

N/DN Tank (#10)

Mainstream Cold Anammox Cyclones (#16)

Outlet (#14)

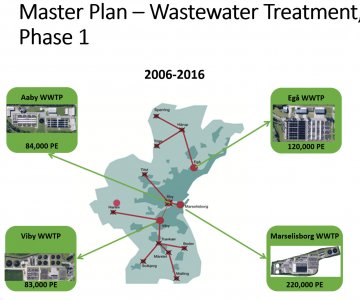

So that concludes the tour of Egå and the future of wastewater. That means currently on this blog I have given an overview of both Egå and Marselisborg WWTP leaving Viby and Åby still left to tour. There is a lot of knowledge still left to share… until next time.

Ingen kommentarer endnu